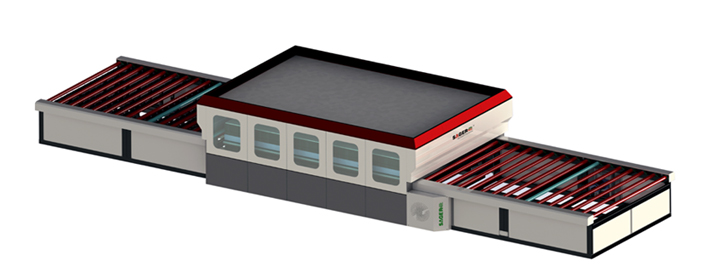

The Automatic Non-Autoclave PVB Laminated Glass Production Line is specially designed for mass production of large-size laminated safety and architectural glass. Using standard PVB interlayer film and a vacuum lamination process, it eliminates the need for an autoclave while ensuring strong adhesion, high transparency and stable quality.

The complete laminated glass line includes an automatic glass loading table, glass washing machine, automatic positioning table, glass assembly table, vacuum handling system, automatic PVB film rack, PVB laminating furnace and unloading table. The system realizes fully automatic loading, washing, positioning, film feeding and cutting, glass assembly, lamination and unloading. It is an ideal solution for factories that require efficient, continuous production of large PVB laminated glass.

Key Features

-

Non-autoclave PVB lamination technology

-

Produces high-quality laminated glass with normal PVB film

-

No autoclave required, reducing investment and maintenance costs

-

-

Fully automatic glass handling

-

Automatic loading and unloading of glass sheets

-

Automatic positioning for accurate alignment of multi-layer glass

-

Vacuum handling to protect glass surface and improve safety

-

-

Integrated film feeding and cutting

-

Automatic PVB film releasing, cutting and laying

-

Precise control of film overlap and trimming

-

Stable and repeatable lay-up quality

-

-

High-efficiency laminating furnace

-

Optimized temperature and vacuum control for strong bonding

-

Uniform heating for large glass sizes and different thicknesses

-

Short cycle time and low energy consumption

-

Advantages for Glass Processors

-

Lower investment compared with traditional autoclave laminated glass lines

-

Simplified process, easy to operate and maintain

-

Flexible production for various glass sizes and thickness combinations

-

Stable quality for architectural, safety and decorative laminated glass

-

Suitable for large pieces and bulk production, improving output and productivity

Typical Applications

-

Architectural laminated glass for facades, doors and windows

-

Safety glass for railings, canopies, partitions and curtain walls

-

Sound-insulating and UV-blocking laminated glass

-

Interior decorative laminated glass

| Model | Elite series |

| Max.Glass Size | 3660×2440 mm, 4300×2500 mm, 5000×2600 mm, 6000×2600 mm, 8000×2600 mm, 10000×2600 mm |

| Control System | PLC with touch screen |

| Heating temperature | 0–160 °C |

| Conveyor speed | 5–10 m/min |

| Voltage | Customized |

| Dimension | 40000*3500*2200mm |